Technical Data

MATRIX sewage treatment systems are designed to optimise process efficiency, minimise running and maintenance costs and to be as simple and cost effective as possible to install.

Matrix systems are available as a standard single structure 'unitank' design up to residential population equivalents of 300 and thereafter larger systems become a modular design.

The MATRIX sewage treatment system is designed to achieve the minimum required effluent quality standard of 20mg/litre Biochemical Oxygen Demand (BOD) : 30mg/litre Suspended Solids (SS) : 20mg/litre Ammoniacal Nitrogen (NH4), which in European Standard performance testing relates to an efficiency of better than 94%. The certified performance of the MATRIX system is that it produces an average final effluent quality of 11mg/litre Biochemical Oxygen Demand (BOD) : 16mg/litre Suspended Solids (SS) and 7mg/litre Ammoniacal Nitrogen. This relates to an average efficiency ratio of 96.2%, better than most other manufacturers, with individual test efficiency results being as high as 98.8%. As part of the test procedure the MATRIX system was proven to have one of the lowest operating costs.

If a more stringent standard of final effluent quality is required by the Environment Agency, we can normally design to achieve this.

All of our treatment plants have a standard inlet invert depth, but in keeping with our commitment to customer satisfaction and to keep installation simple, we can manufacture our units to specifically meet site requirements. Integral pumped discharges can also be provided with all units, eliminating the need for additional tankage and installation costs

All Matrix systems are complete with failure alarms as standard (as required by BSEN12566-3) and are not, as with some other companies in this industry, an optional additional cost item.

The MATRIX treatment system is a three stage biological process contained within a single tank structure, based on the principles of a submerged bed reactor and designed in accordance with the requirements of BS6297. Careful configuration of the internal flowpath and the inclusion of non-mechanical recirculation systems ensures optimal process performance as demonstrated by the exceptional results obtained from the independent testing, providing complete peace of mind for the end user. There are NO electrical or mechanical components within the treatment plant thereby eliminating the need for any specialist servicing arrangements ensuring that any maintenance requirements on the MATRIX system are kept to an absolute minimum

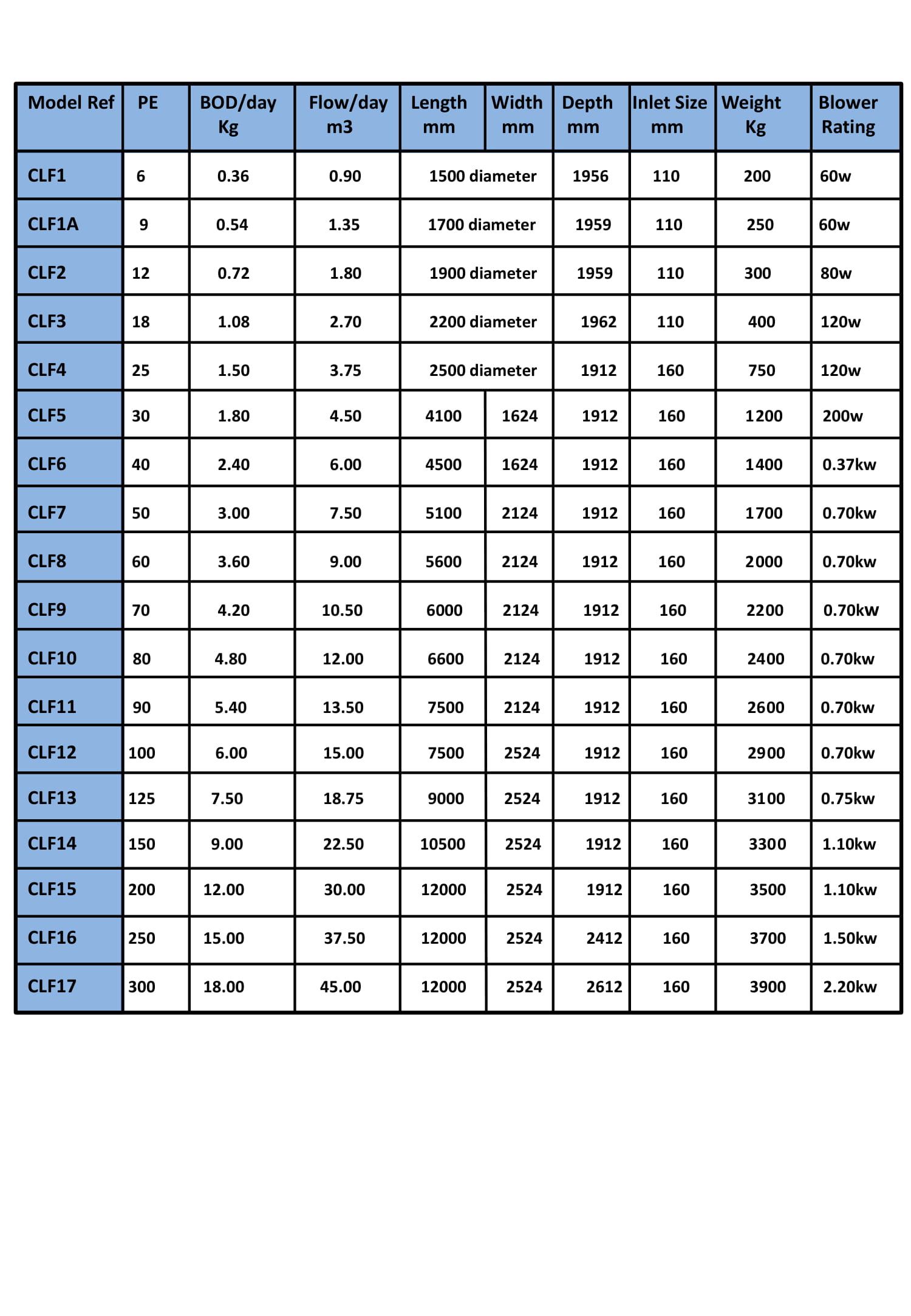

MATRIX STANDARD RANGE DATA TABLE

- Clenviro reserve the right to alter specifications without prior notice.